Metal Forming Industry

High-Performance Blades for Precision Metal Processing

Indian Knives & Tools Co. supplies advanced cutting tools and industrial blades that support the demanding needs of the metal forming and processing industry. Our precision-engineered knives are designed to deliver superior durability, clean cuts, and extended operational life, even under the toughest working conditions.

Whether you’re processing stainless steel, carbon steel, copper, aluminum, or high-strength alloys, our knives provide optimal performance in shearing, slitting, and trimming operations.

Our Solutions for Metal Forming Applications:

We offer a comprehensive range of precision-engineered solutions tailored to meet the demanding requirements of metal forming industries. Our tools and components are designed to deliver superior performance, durability, and accuracy in high-pressure and high-precision environments.

Shear Blades – For coil and sheet cutting

Slitter Knives – For longitudinal cutting of metal strips

Cropper Knives – For cutting hot or cold rolled bars and billets

Trimmer Knives – For edge trimming during coil processing

Circular & Straight Blades – Custom-engineered for OEM compatibility

Metal Forming Industry

Our blades are widely used in diverse metal forming applications, including:

- Automotive Industry – Cutting body panels, exhaust pipes, and roll-formed components.

- Construction & Roofing – Processing metal roofing sheets, channels, and support beams.

- Steel Coil & Sheet Processing – Slitting, shearing, and cutting stainless steel and aluminum sheets.

- Furniture & Storage Systems – Cutting metal frames, racks, and modular shelving.

- Electrical Industry – Precision cutting of transformer laminations and electrical steel.

CNC Die-Cast Dies

Shear Blades

Mild Steel Forming Rolls

Guide Rollers

Track Followers

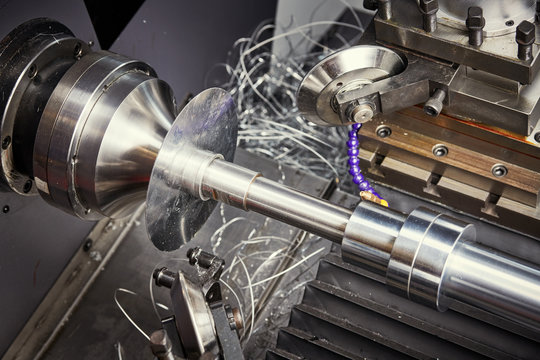

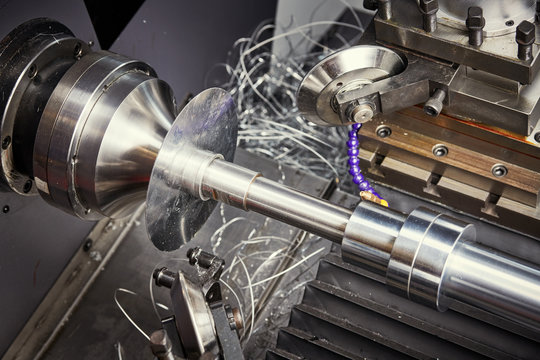

Metal Forming Process

Why Choose Our Metal Forming Blades?

- High-Precision Cutting – CNC-machined and heat-treated for optimal sharpness and durability.

- Extended Tool Life – Made from premium-grade steel and tungsten carbide, ensuring long-lasting performance.

- Minimal Burr Formation – Designed to deliver clean and accurate cuts, reducing the need for secondary processing.

Custom Blade Solutions – Tailored for specific metal forming machines and applications.