Products Categories & Description

Granulator Blades

Our Granulator Blades are engineered for high-speed plastic shredding and granulating operations. Manufactured from premium-grade alloy steels, these blades deliver superior durability, cutting accuracy, and wear resistance for continuous processing.

Key Features:

Precision ground for consistent cutting

Available in standard and custom profiles

Made from D2, M2, or Tungsten Carbide

Ideal for plastic film, PET, PVC, and more

Applications:

Plastic recycling, film processing, injection molding regrind

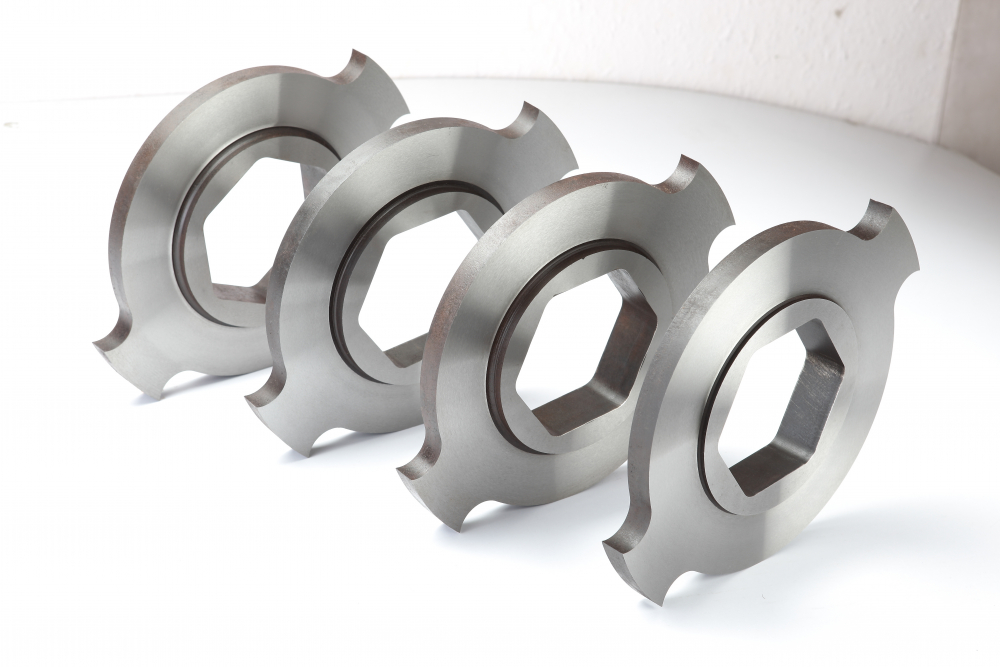

Rotor & Stator Knives

Designed to work seamlessly together, our Rotor and Stator Knives offer clean, controlled cutting for demanding recycling operations. Using CNC-machined profiles and advanced heat treatment, we ensure each knife delivers optimal efficiency and long service life.

Key Features:

Tight tolerances for exact fit and smooth operation

Manufactured in various tooth configurations

Suitable for heavy-duty shredders and granulators

Available in D3, D2, CRU-WEAR, and customized options

Applications:

Shredding and chopping of plastics, textiles, rubber, and light metals

Shredder Blades

Our Shredder Blades are built to handle the toughest industrial applications, including high-impact and abrasive materials. Engineered from wear-resistant steel, these blades maintain sharpness and structural integrity through continuous cycles.

Key Features:

Available in single-shaft, double-shaft, or four-shaft designs

Designed for maximum throughput and minimal downtime

Hardness balanced for strength and resistance

Custom-built for any shredding system

Applications:

Plastic drums, metal scrap, e-waste, wood, industrial waste

Pelletizer Blades

Crafted for precision and longevity, our Pelletizer Blades ensure clean and uniform cutting of plastic pellets. These blades are designed for smooth rotation and consistent performance, reducing fines and improving pellet quality.

Key Features:

Mirror-finished edges to reduce material build-up

Uniform cutting action and minimal vibration

Available in HSS, D2, and carbide-tipped versions

Sharpness retention for extended production runs

Applications:

Plastic extrusion, polymer compounding, masterbatch production

Agglomerator Blades

Our Agglomerator Blades are built for thermal compaction of plastic films, fibers, and foams. Designed to withstand high speeds and frictional heat, these blades guarantee consistent flake size and reduced maintenance cycles.

Key Features:

Spiral or straight tooth profiles available

Built for speed, endurance, and aggressive cutting

Ideal for PP, PE, LDPE, and stretch film

Compatible with all major agglomerator machines

Applications:

Film recycling, waste plastic flaking, pre-processing for pelletizing

Products Categories & Description

Granulator Blades

Designed for efficient size reduction of plastic and rubber waste. Manufactured with high wear resistance and precision grinding, these blades ensure long service life.

- Material Options: D2, D3, M2, Tungsten Carbide

- Applications: Plastic Recycling, Granulating Machines

Rotor & Stator Knives

Our rotor and stator knives deliver optimal cutting performance for various industrial applications. Designed for high-strength and impact resistance.

- Material Options: D2, CRU-WEAR, Tungsten Carbide

- Applications: Recycling, Shredding, Plastic Processing

Shredders

Industrial shredder blades ensure high durability and efficient shredding of plastic, rubber, and metal waste. Custom-made to meet industry-specific requirements.

- Material Options: D2, M2, T1, Tungsten Carbide

- Applications: Industrial Waste Management, Scrap Processing

Agglomerator Blades

Designed for high-speed plastic recycling and processing, our agglomerator blades ensure smooth operation and high efficiency.

- Material Options: D2, M2, Tungsten Carbide

- Applications: Plastic Agglomeration, Film Recycling

Material Grades We Offer

DIN 1.2379/D2 – High wear resistance for shredding

DIN 1.2080/D3 – Suitable for applications & high toughness

DIN 1.3343/M2 – High-speed steel for extreme durability .

DIN 1.3355/T1 – Superior hardness for metal cutting

Tungsten Carbide – Best for heavy-duty applications

CRU-WEAR – Excellent toughness & wear resistance